Mixed-flow vs. Axial-Flow and understanding the benefits and advantages of both.

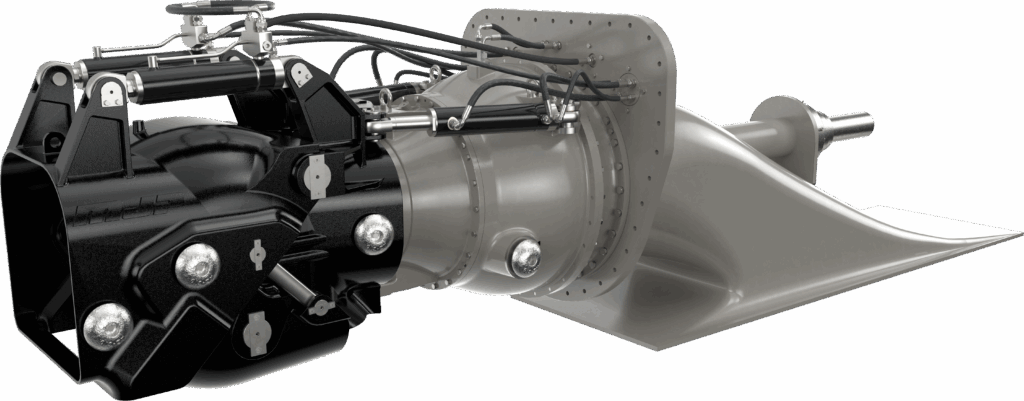

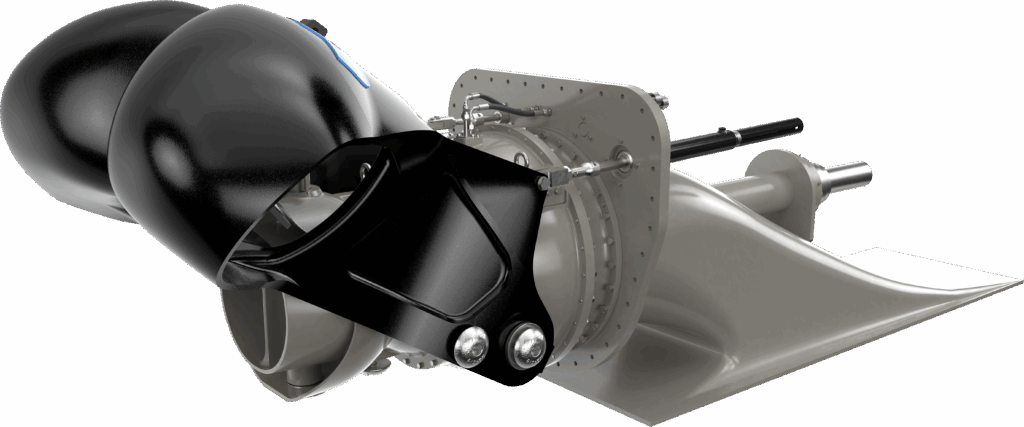

Axial-Flow is where the flow comes into the intake the diameter of the intake is the same as the impeller diameter so the flow remains in an axial direction.

· Efficient at lower speeds and high thrust

· High-thrust capability / Bollard Pull

· Large Payload – get on plane even with a boat-full of fish or cargo

· Popular applications include: Commercial Fishing and Commercial Workboats that have large payloads or a bollard pull requirement

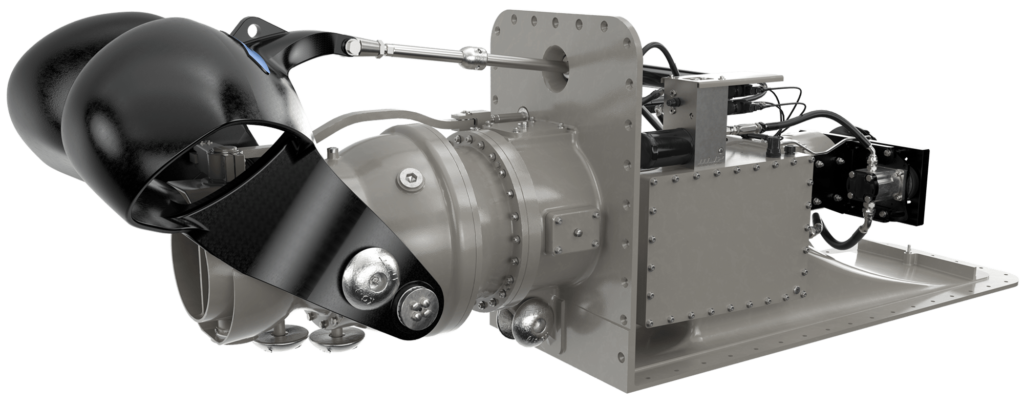

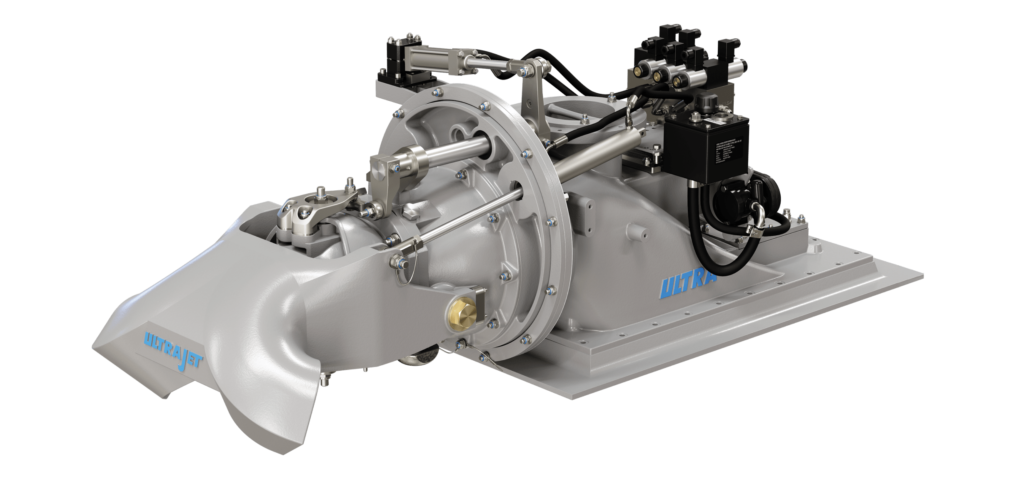

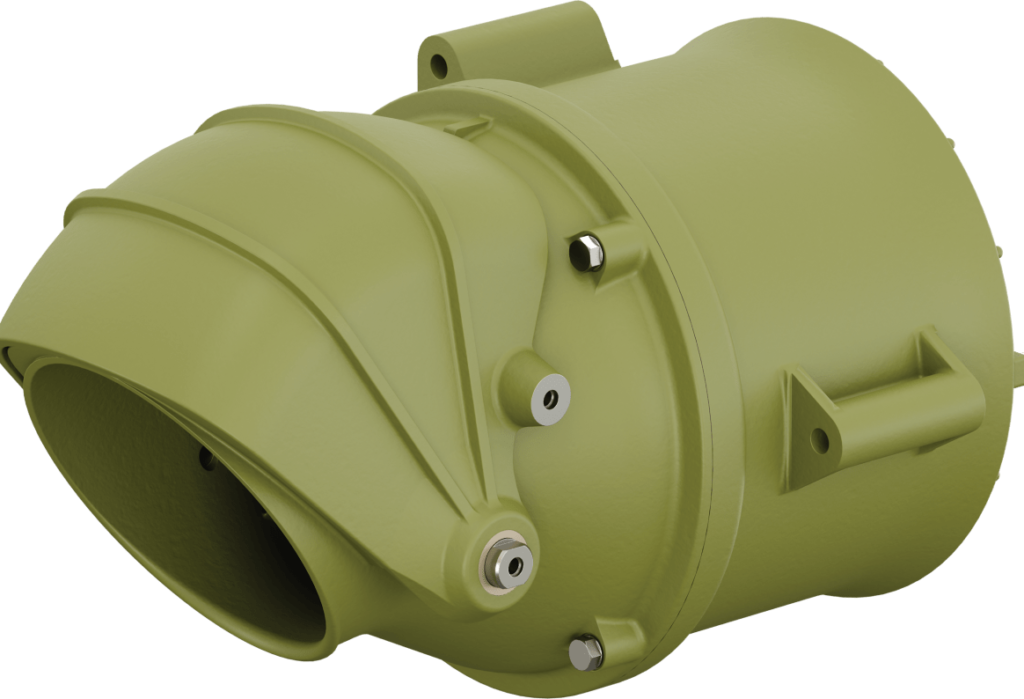

Mixed-flow is where the impeller diameter is larger than the intake diameter therefore as the flow comes in, water radially wraps around the pump creating radial flow and axial flow creating mixed-flow. At high speeds the efficiency is far greater. Because like a centrifugal pump, mixed-flow handles the flow rates into the pump more efficiently. Resulting in a more efficient waterjet, running on either less power or saving fuel.

· Efficient at high-speed

· High propulsive efficiency across the speed range

· Popular applications include: High-speed military craft, fast response boats

Both Mixed and Axial-Flow have their advantages and best use cases. To best optimize the performance of your next waterjet vessel, contact your MJP sales rep.