Waterjets for CTVs: Debunking the Myths

Read the full article here.

With more wind farms sprouting up in Europe, Asia and now here in the United States, a steady stream of crew transfer vessels (CTV) will be needed to support their construction, maintenance and operation. Typically aluminum catamarans, these vessels are deployed to ferry personnel and light equipment to and from offshore wind farms on a daily basis.

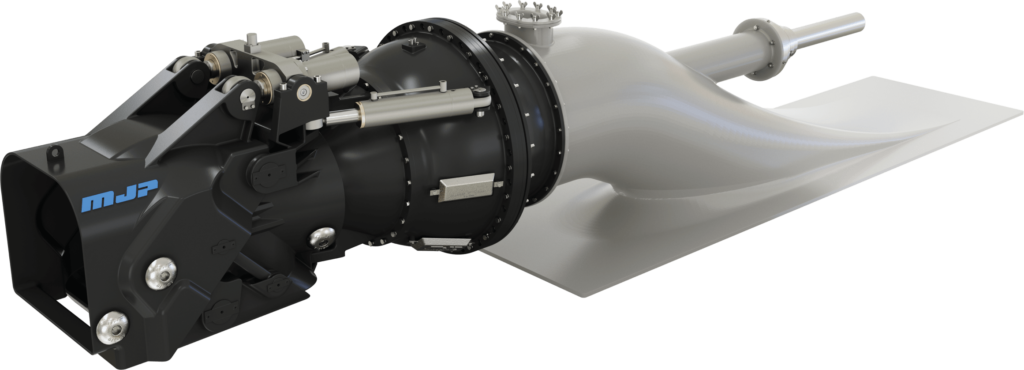

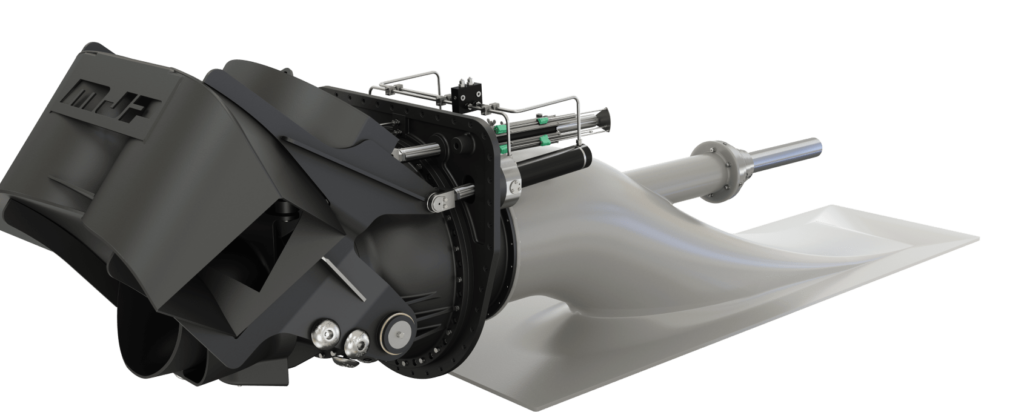

While a solid portion of CTVs in the established European offshore wind market are propelled by waterjets, Adam Mills, sales director at Marine Jet Power, says there are still a lot of misconceptions about the propulsion solution floating around the industry.

Performance

One common myth, Mills says, is that waterjets don’t perform well in high sea states or extreme wind and tidal conditions. “Our waterjets perform exceptionally well in rough conditions,” he says.CTVs operating in high sea states often encounter turbulent, ever-changing sea conditions that put the vessel through all six ship motions, but it’s mainly pitch, roll and heave that affect the propulsion system, Mills explains. “The effect of these motions only become a concern if the vessel has a shallow hull deadrise, low draft and operating at extremely high speeds where air can be drawn into the waterjet intakes,” he says. “In our 35 years’ experience, it is extremely rare that this becomes a concern. On a vessel running at CTV transit speeds in extreme conditions, the waterjet intake stays comfortably deep enough to ensure the pump is well primed and non-aerated laminar water flow is ingested.”

Mills adds that MJP’s efficient pump design and steering system provide high thrust and maneuverability ensuring the vessel stays on course in extreme conditions. “This is especially important when approaching the wind turbine in heavy seas to transfer crew,” Mills notes. “Waterjets operate independently allowing true sidling motion of the vessel, between the bucket and steering nozzle. The operator has 360-degree precise maneuverability. With waterjets installed, a vessel can rotate 360 degrees in its own boat length. For CTVs in prevailing wind conditions, this makes crew transfer much more precise and safer.”

Cost

While the upfront cost to purchase waterjets can often seem more expensive compared to fixed propeller options, Mills says CTV owners and operators should consider the complete lifecycle cost when weighing their propulsion options. “As a general statement, waterjets don’t overload the engine in varying sea states and loading conditions like conventional propellers. Therefore, with a waterjet vessel you won’t need to replace your engines,” he says.

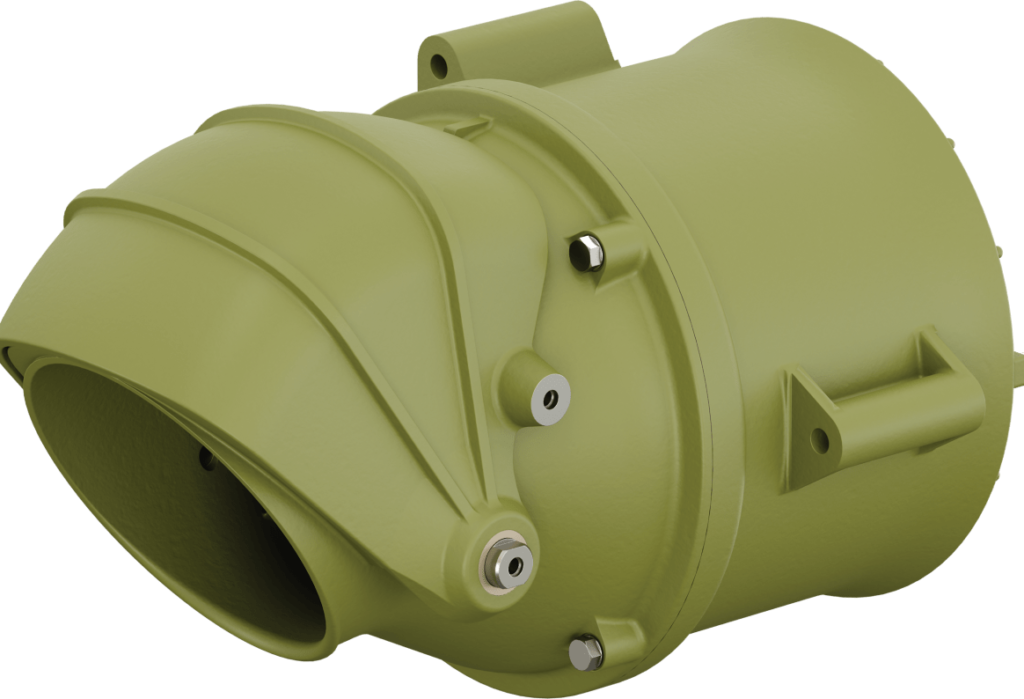

According to Mills, MJP waterjet users will encounter very little annual service costs due to their duplex stainless steel construction and the company’s standard five-year warranty. “You can run our waterjets for 5,000 hours in the first year and only the anodes and oil filter will need to be replaced. Now the lifecycle costs start to look much more attractive in favor of waterjets.”

Mills claims MJP’s “highly-efficient” mixed-flow pump design and duplex stainless steel construction gives an extra efficiency boost that translates not only into fuel savings, but time savings as well. “Transit times can be reduced, meaning more time to service and maintain wind turbines.”

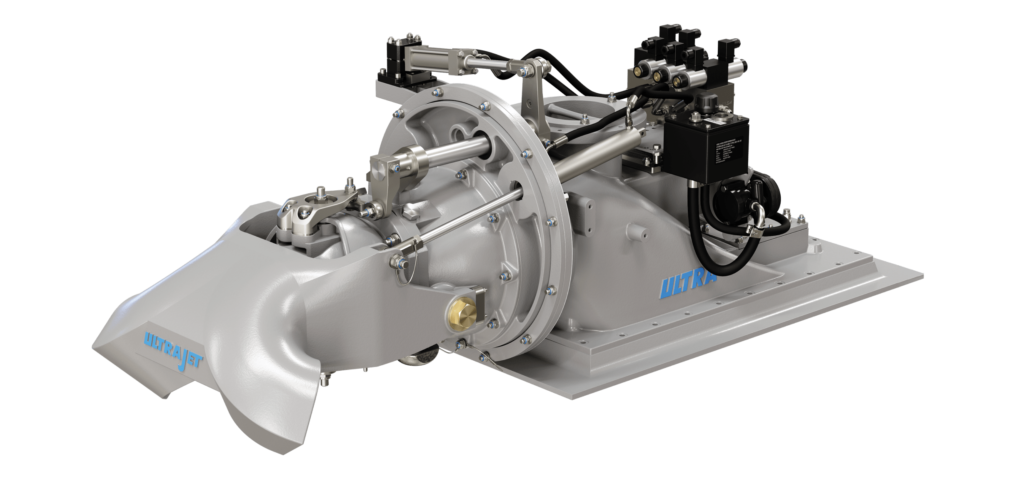

In addition, Mills says MJP recently expanded its X-Series waterjet range to offer sizes up to 500X/ 2070 kW, meaning builders can benefit from a larger class approved waterjet that is a one piece bolt-on or weld-in installation. “The X-Series waterjets are very easy to install, shipped as one piece and installed as one piece, significantly lowering the man hours needed to complete the vessel. This was done with extensive research and feedback from builders around the world.”

Crew Comfort

Mills says another common myth about waterjets is that they reduce comfort for the captain and crew, but he notes MJP’s recently launched dynamic positioning (DP) system for its JetMaster 3 electronic control solution has been created with CTV operations in mind. “There are more than 60 CTVs equipped with MJP waterjets; we understand the industry and the vessels’ mission,” Mills says.

The adaptive DP system has four operational modes and is designed to make station keeping in prevailing wind and tide conditions comfortable for loitering vessels. “Our DP system is designed so that once the maintenance crew have been transferred safely to the turbine, the captain can step away from the helm in confidence that the vessel will stay on station and hold heading while waiting for the crew to finish their service work on the turbine, sometimes for several hours. The DP system therefore helps reduce tiredness of the captain while saving fuel because it applies precise control when its needed.”

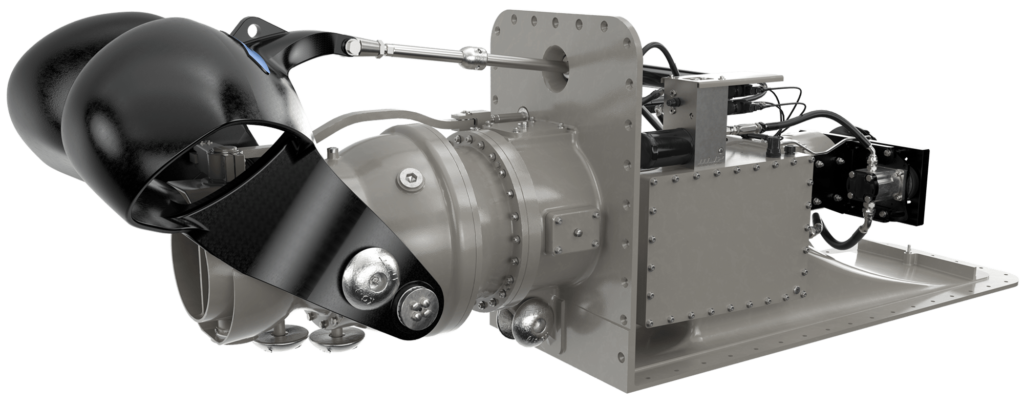

Wildlife

It’s common for people to believe that waterjets can be harmful to marine mammals and other marine life, but Mills says this simply isn’t the case. “When it comes to protecting wildlife, waterjets are the best propulsion solution because they have intake grills, and all rotating parts inside the vessel and above the hull bottom,” he says. “This is why waterjets are often the preferred solution when operating in areas where marine life is prevalent and protected, and also where a vessels operation is recovering personnel within the surrounding waters, such as dive boats and search and rescue vessels.”