How are Waterjets Made?

Waterjet propulsion systems have become an integral part of marine technology, enabling efficient and powerful propulsion for vessels around the world. This video shows an exclusive behind the scenes look of how waterjets are made. To begin, let’s explore the initial stages of waterjet construction at Österby Gjuteri, one of Sweden’s most renowned foundries and MJP’s partner in this venture.

MJP’s journey into waterjet manufacturing began in collaboration with Österby Gjuteri, a foundry steeped in history as one of Sweden’s oldest foundries. Today, Österby Gjuteri has evolved into Northern Europe’s premier supplier of complex steel castings. This partnership laid the foundation for the production of high-quality waterjet propulsion systems.

The process of creating MJP waterjets starts with the development of intricate patterns, which serve as templates for the final components. These patterns are meticulously crafted to ensure precision and accuracy in the casting process. Once the patterns are ready, they are fitted into casting molds, marking the beginning of the waterjet’s creation.

The next step involves filling these molds with molten steel sourced directly from the furnace. This crucial phase requires precise control of temperature and pouring to achieve the desired quality and strength of the cast components. After the steel has been poured, a cooling period is allowed to ensure the components solidify correctly.

Following the cooling period, the cast components undergo a critical process known as fettling. During fettling, excess material and imperfections are carefully removed from the castings. This step is essential to ensure that the components meet the high-quality standards expected of MJP waterjets.

After fettling, the components proceed to the heat treatment stage. Heat treatment is a controlled process that imparts specific mechanical properties to the steel, enhancing its durability and performance. This step further strengthens the waterjet’s components, ensuring their longevity in demanding marine applications.

Once the cast components have been fettled and heat-treated, they are transferred to the machine shop. In the machine shop, precise milling and drilling operations are carried out. These machining processes are vital to achieve the exact specifications required for each waterjet.

Balancing is a critical step in the manufacturing process of waterjets. It ensures that the components are well-balanced, reducing vibration and ensuring smooth operation. Additionally, comprehensive measurements and quality checks are performed to guarantee that each component meets the stringent quality and tolerance standards set by MJP.

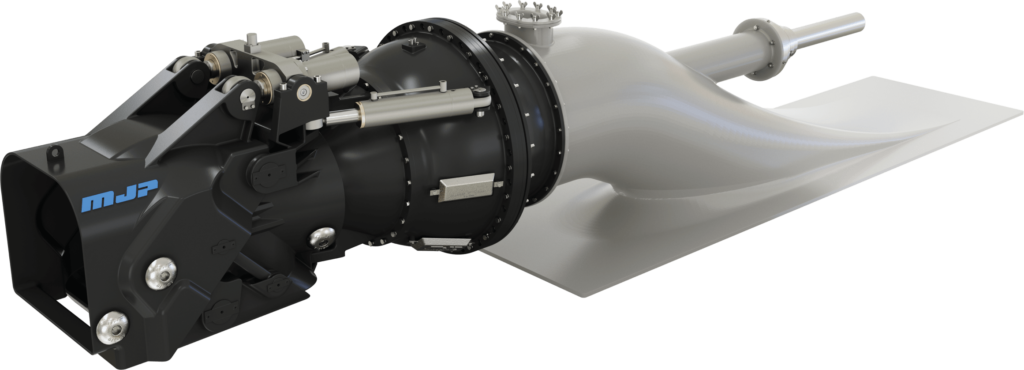

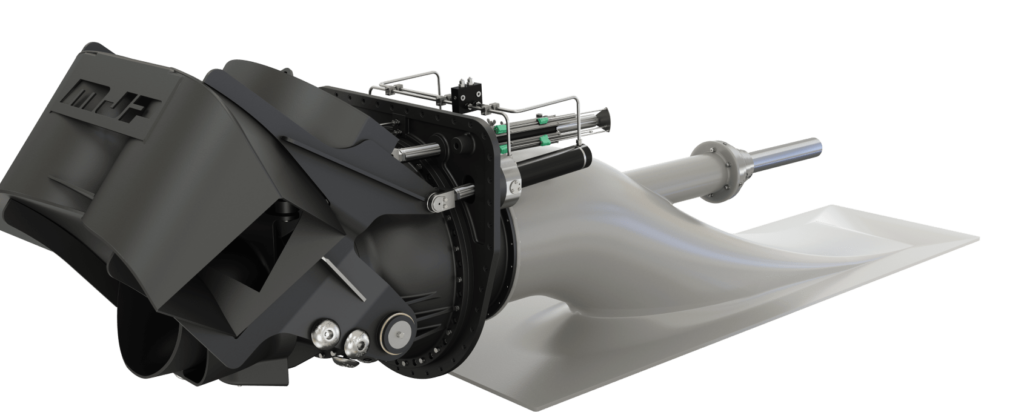

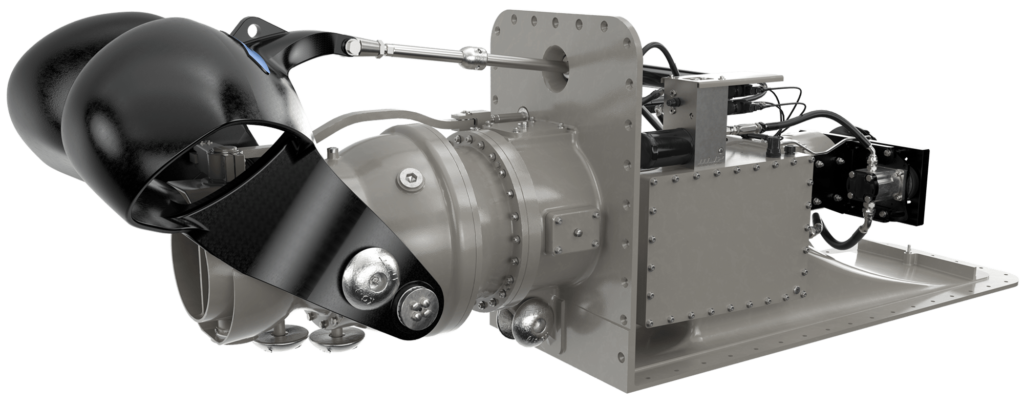

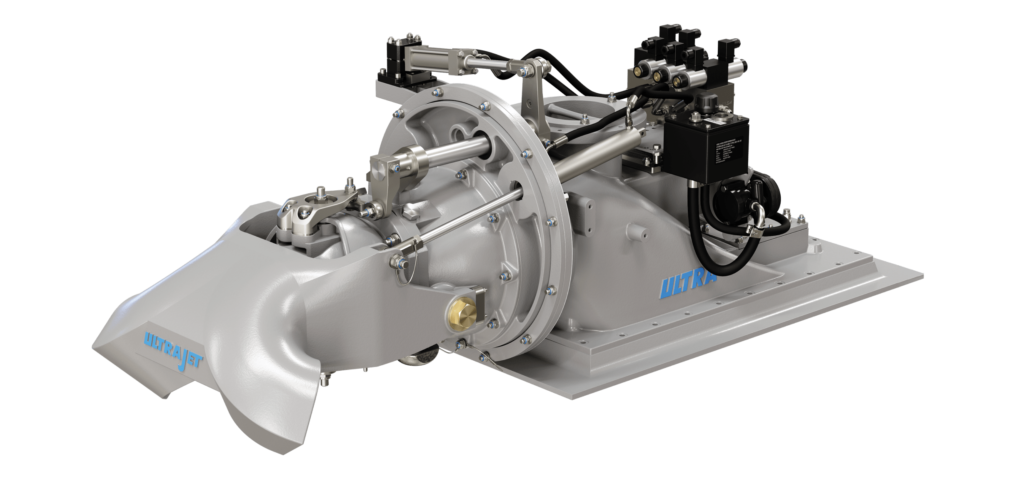

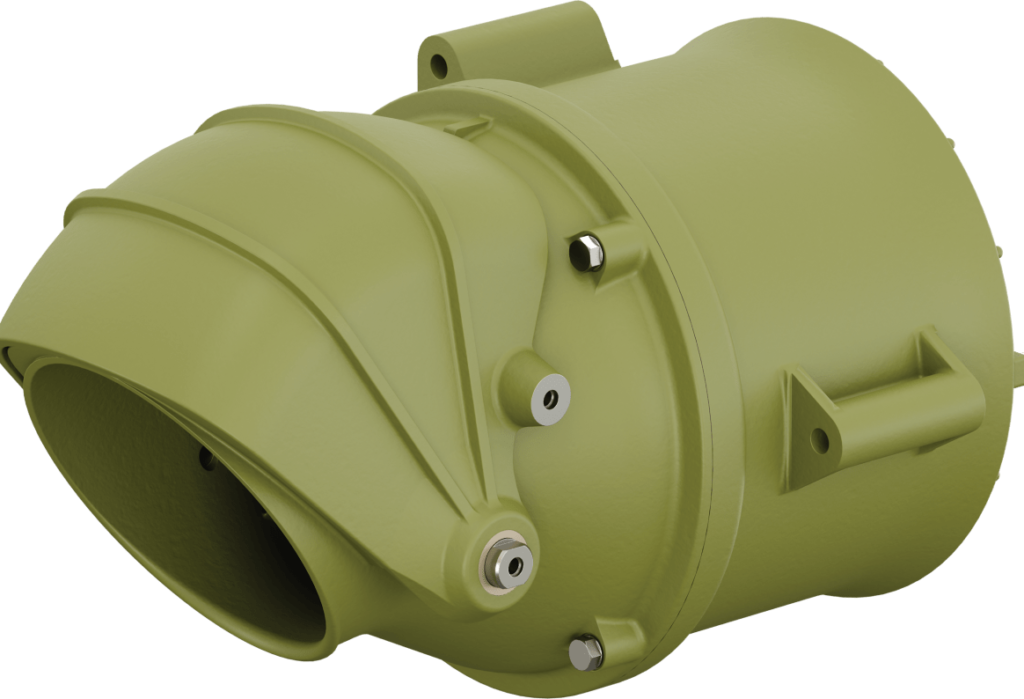

After passing through the rigorous quality control measures, the waterjet components are ready for final assembly. This assembly takes place at the MJP facility, where skilled technicians meticulously put together the various components to create the complete waterjet propulsion system.

Before delivery to customers, the assembled waterjets receive their final touch – a protective paint coating that not only enhances their appearance but also provides corrosion resistance, crucial for marine applications. Once painted and thoroughly inspected, the waterjets are ready to power vessels in various marine environments.

The journey from the foundry to the final assembly facility is a testament to the precision and dedication that goes into manufacturing MJP waterjets. These propulsion systems, constructed from duplex stainless steel, undergo a series of intricate processes to ensure their reliability, efficiency, and longevity in the demanding world of marine propulsion.