What is Impeller Tip Clearance?

Impeller tip clearance is the gap between the impeller blades and the pump casing. The importance of having a very low tip clearance is directly related to propulsive efficiency.

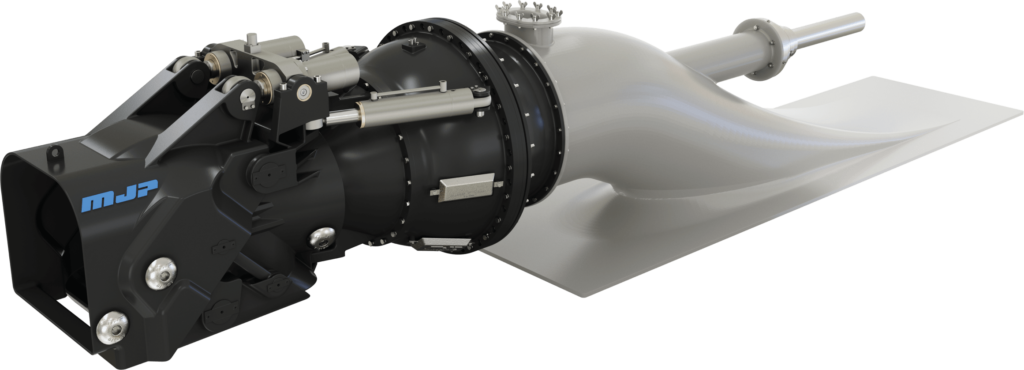

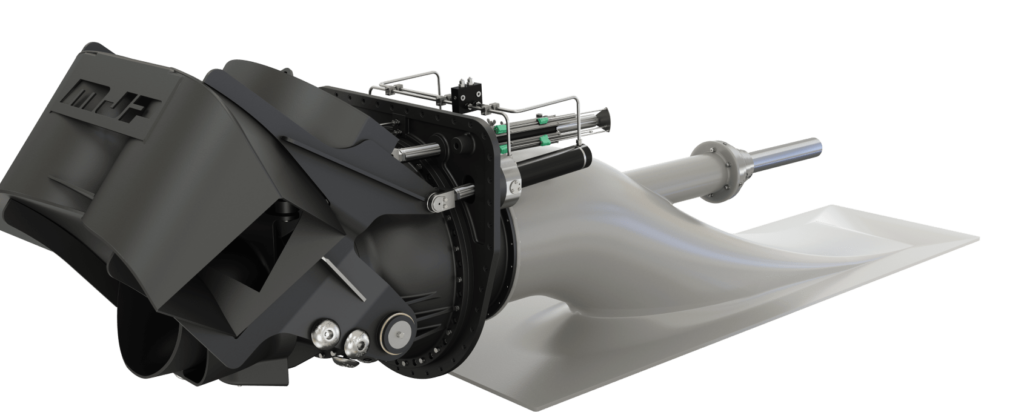

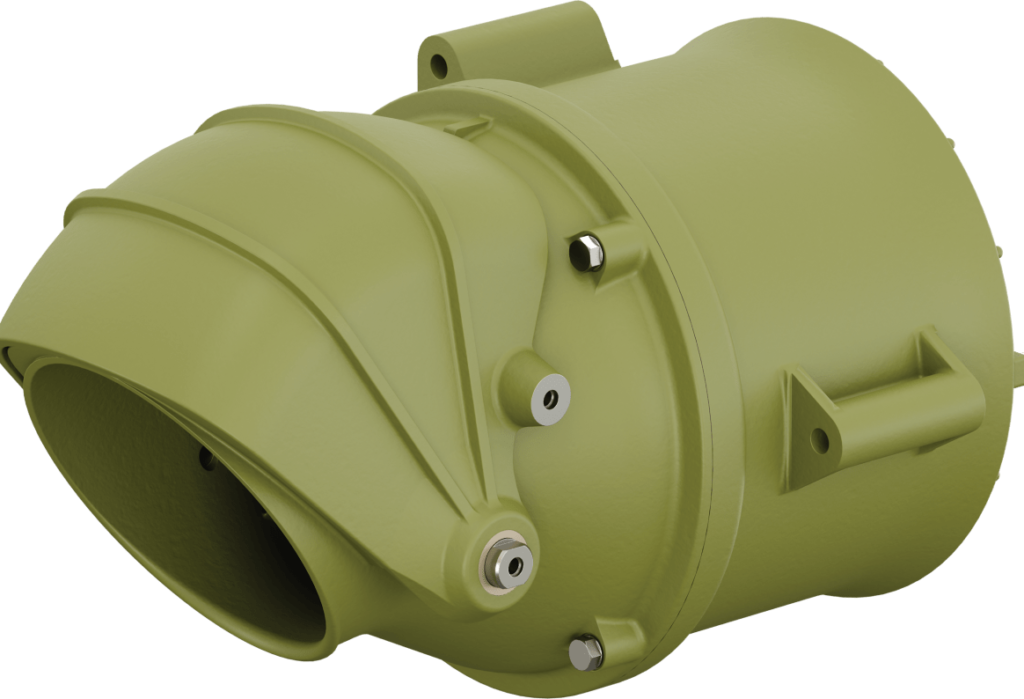

Because MJP’s CSU, DRB and X-Series waterjets are all manufactured from duplex stainless steel, there is no need for a wear sleeve or an impeller liner.

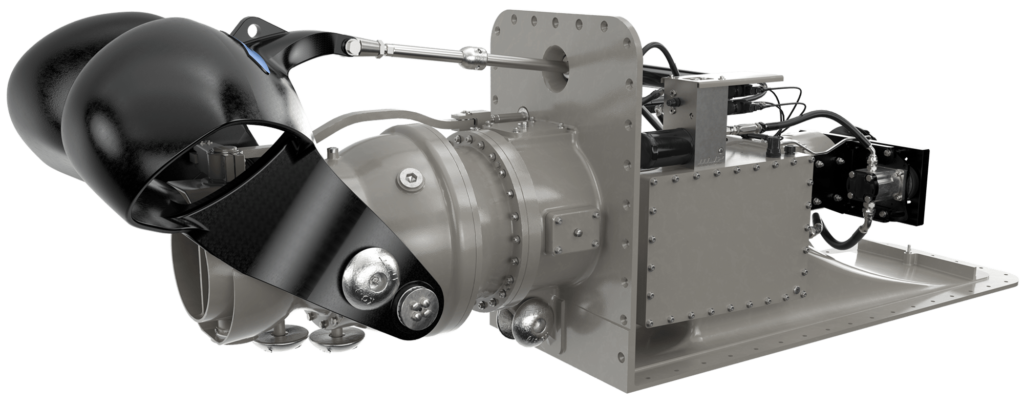

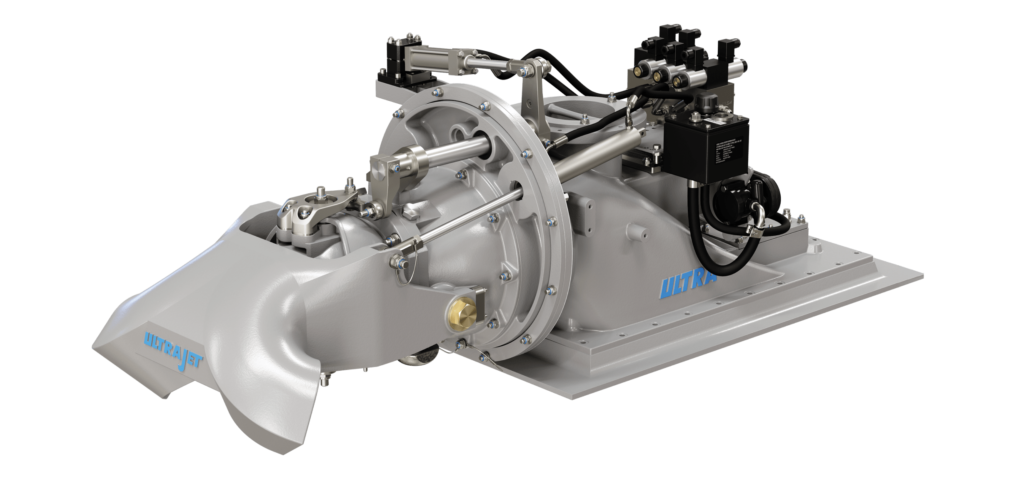

In an aluminum waterjet, a wear ring or impeller liner is needed to separate dissimilar metals to prevent corrosion, which enlarges the tip clearance gap. However, in waterjets where the pump unit is fully constructed from duplex stainless steel this addition is not needed.

This construction method allows MJP to offer very tight tip clearances in its stainless-steel jets to offer the maximum in efficiency.

MJP ensures the best tip clearance through a shim-plate located at the forward end of the drive shaft. So when the waterjets are assembled adjustments can be made to the shaft and impeller, which closes out the tip clearance on the mixed-flow hub, ensuring the perfect fitment for the most efficient waterjets on every delivery.